Top 10 Applications of GRP Grating in Industrial Settings

Introduction

GRP Grating has become an essential material across numerous industries due to its exceptional durability, corrosion resistance, versatility, and long-term cost efficiency. As industries shift toward safer and more sustainable infrastructure solutions, GRP Grating continues to stand out as a superior alternative to steel, wood, and traditional metal gratings. Its lightweight structure, non-conductive properties, and remarkable load-bearing strength make it suitable for environments where safety and reliability are top priorities. In this comprehensive article, we explore the top 10 applications of GRP Grating in industrial settings, analyzing its benefits, suitability, and the reasons behind its increasing global demand. Throughout this guide, we highlight how GRP Grating transforms industrial operations and why it remains a preferred choice for engineers, facility managers, and construction professionals.

1. Walkways and Platforms

GRP Grating is widely used in industrial walkways and platforms, especially in areas exposed to heavy moisture, chemicals, or abrasive environmental conditions.

Corrosion Resistance for Extreme Environments

In chemical plants, desalination facilities, and wastewater treatment units, metal walkways often rust over time, requiring constant maintenance. GRP Grating eliminates this issue due to its naturally corrosion-resistant fiberglass structure.

Enhanced Worker Safety

The anti-slip surface of GRP Grating significantly reduces workplace accidents, even in oily or wet conditions. Additionally, its non-conductive nature makes it safer for environments where electrical hazards may be present.

2. Stair Treads and Staircase Systems

Industrial staircases undergo heavy usage daily, making durability essential. GRP Grating provides reinforced strength without adding excessive weight.

Lightweight but Strong

The lightweight characteristic of GRP Grating makes installation easier and reduces strain on supporting structures. Despite being lightweight, it offers impressive load-bearing capabilities.

Customizable and Reliable

GRP Grating can be manufactured in various panel sizes and thicknesses, ensuring it fits any staircase system precisely while maintaining safety and stability.

3. Chemical Processing Plants

Chemical processing environments are some of the harshest for construction materials. GRP Grating is ideal because it remains unaffected by chemical vapors, spills, and fumes that typically degrade metals.

Chemical Resistance as a Major Advantage

GRP Grating stands strong against acids, alkalis, solvents, and industrial chemicals. This ensures longer operational life and reduced replacement costs.

Ideal for Hazardous Zones

Its non-sparking and non-conductive properties contribute to safer work zones, making GRP Grating essential in volatile industrial environments.

4. Offshore and Marine Applications

Offshore oil rigs, ports, and marine facilities expose materials to saltwater, moisture, and high winds—all factors that deteriorate steel. GRP Grating outperforms traditional materials in these settings.

Saltwater-Proof Construction

The corrosion resistance of GRP Grating makes it perfect for marine platforms, docks, catwalks, and ship decks.

Longevity in Harsh Conditions

Unlike metal, which corrodes rapidly, GRP Grating maintains structural integrity for decades, reducing maintenance needs and downtime.

5. Wastewater Treatment Plants

Wastewater environments require materials that can withstand constant exposure to moisture, harsh cleaning chemicals, and gases. GRP Grating is a top choice here.

Low Maintenance Operation

GRP Grating does not degrade over time, making it a cost-effective long-term solution for treatment plant floors, walkways, and elevated platforms.

Resistant to Microbial Growth

Its surface composition resists algae, mold, and bacterial growth, improving hygiene and reducing slip risks.

6. Electrical and Power Plants

Electrical plants require materials that are non-conductive and safe. GRP Grating meets these requirements while offering additional safety benefits.

Non-Conductive and Safe

GRP Grating eliminates the electrical conductivity found in metal gratings, making it indispensable in power stations, control rooms, and transformer areas.

Fire Retardant Capabilities

Many GRP Grating options are engineered with fire-retardant resins, making them suitable for high-risk environments.

7. Food Processing Facilities

Food production factories need flooring and platforms that remain hygienic, easy to clean, and resistant to contaminants. GRP Grating excels in these applications.

Hygienic Material Composition

The smooth surface and non-porous nature of GRP Grating help maintain sanitary conditions and comply with industry regulations.

Slip-Resistant and Easy to Wash

Frequent cleaning and moisture exposure do not affect GRP Grating, making it ideal for food processing walkways, platforms, and inspection areas.

8. Mining and Mineral Processing

Mining environments demand robust and reliable materials capable of resisting abrasion, heavy loads, and harsh chemicals. GRP Grating consistently meets these needs.

High Load-Bearing Capacity

GRP Grating can withstand heavy equipment and foot traffic without warping or cracking.

Impact Resistance

It resists sudden impacts and vibrations common in mining operations, providing long-lasting, dependable performance.

9. Cooling Towers and HVAC Facilities

Cooling towers are highly corrosive environments due to moisture and chemical treatment processes. GRP Grating offers resilience and safety.

Ideal for Constant Moisture Exposure

GRP Grating does not rust, rot, or corrode, making it ideal for walkways, ladders, and platforms in cooling tower infrastructure.

Lightweight for Easy Maintenance

Cooling tower maintenance often requires frequent inspections. The lightweight nature of GRP Grating simplifies inspection processes and reduces downtime.

10. Transportation and Infrastructure

From railways to pedestrian bridges, GRP Grating is increasingly used in public and industrial infrastructure projects.

Long-Lasting and Weather-Resistant

GRP Grating withstands extreme temperatures, humidity, and rainfall, making it a favorite for outdoor installations.

Versatile Applications

It is used for bridge decking, pedestrian walkways, railway crossings, maintenance platforms, and drainage covers. Its long service life reduces operational costs for public authorities and private developers.

Key Advantages of GRP Grating Across Industries

To better understand why GRP Grating is one of the most sought-after industrial materials, it is essential to highlight its overall advantages.

Superior Durability

GRP Grating maintains structural performance over long periods, even in high-stress environments.

Exceptional Corrosion Resistance

Its fiberglass and resin composition protects against corrosive chemicals, saltwater, and moisture.

Lightweight for Faster Installation

Being lighter than metal reduces installation labor, structural support needs, and transportation costs.

Safety Enhancements

Its anti-slip surface, non-conductive properties, and fire-retardant capabilities make GRP Grating an essential safety feature in industrial environments.

Minimal Maintenance

GRP Grating requires little to no maintenance, allowing industries to focus on productivity rather than repairs.

Tips for Selecting the Right GRP Grating

Choosing the correct GRP Grating for your facility ensures optimal performance and safety.

Understand Load Requirements

Different environments require varying load capacities, so ensure the chosen GRP Grating meets your structural needs.

Select Appropriate Resin Types

Some GRP Grating products are designed specifically for chemical resistance, fire retardancy, or UV protection. Determine your site’s environmental demands.

Evaluate Surface Finish Options

Anti-slip surfaces vary in texture. Choose according to the frequency of moisture, spills, or heavy foot traffic.

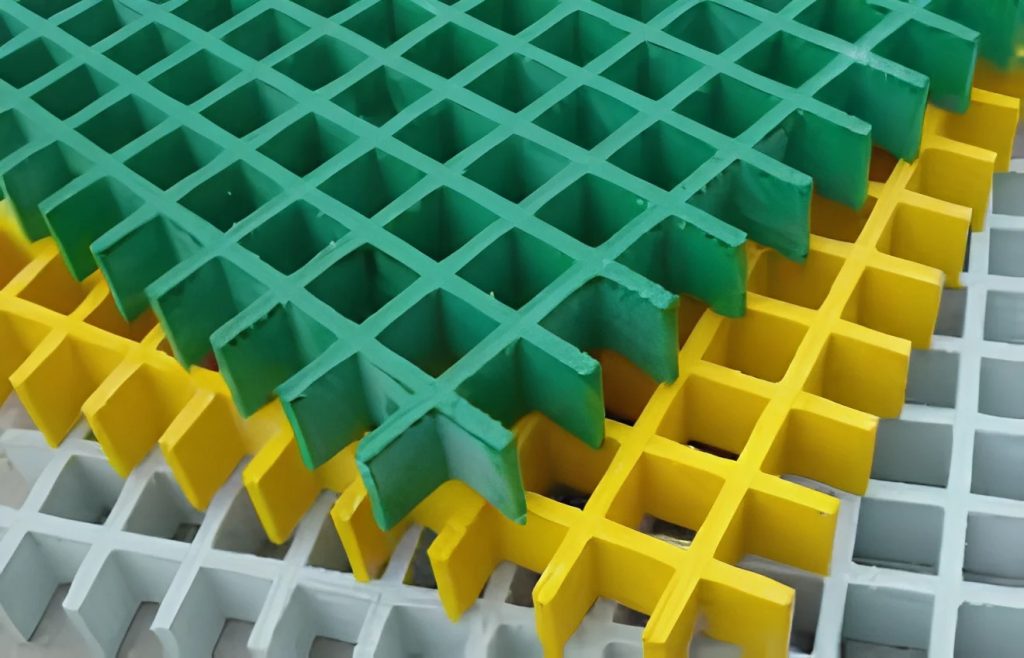

Consider Panel Size and Mesh Pattern

GRP Grating comes in different mesh designs—square, rectangular, mini-mesh—each offering varying advantages for drainage, safety, and equipment compatibility.

Why Industries Prefer GRP Grating Over Metal

While metal has been the traditional choice for decades, the shift toward GRP Grating continues to accelerate.

No Rust, No Rot

Unlike steel, GRP Grating does not need constant painting or galvanizing.

Non-Sparking and Safe

Its non-sparking characteristic is crucial in flammable environments.

Cost Savings Over Time

Initial investment in GRP Grating is offset by its longevity and minimal maintenance cost.

Environmental Benefits

Manufacturing and maintaining GRP Grating generally have a lower environmental impact compared to metal production and replacement cycles.

Conclusion

GRP Grating has evolved into a critical material for modern industrial infrastructure due to its exceptional strength, corrosion resistance, safety features, and cost efficiency. From offshore rigs and chemical plants to food processing facilities and public infrastructure, the applications of GRP Grating continue to expand as industries recognize its unmatched benefits. By understanding its versatility and advantages, businesses can make informed decisions that enhance safety, improve productivity, and reduce maintenance expenses. As industries grow more demanding, GRP Grating remains a reliable, long-lasting solution that meets the highest performance standards across a wide range of environments.